Monday afternoon we put on our rain gear and warm clothes to go to the Quincy Mine just outside of Houghton. This was a very successful mine for almost 100 years for the investors, operating from 1846 to 1945. Getting to go down into the mine was a real treat, especially since we got to “look” the part.

The mine had two main buildings: a brick building for the hoist, and a tall metal building for the shafts to get men into the mine and rocks and water out of the mine. Cables from the hoist building operated the cars in the Shaft house

We asked why copper was so important in the 1800s and were told that it was used on all the telephone and telegraph lines being strung across the U.S., as well as for ammunition.

We took a tram ride to a side opening to the mine where we could enter.

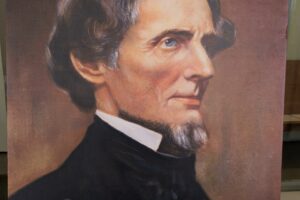

Don’t you just love our new look with the warm coats and hard hats?

The ore was taken out of the mine and carried by rail car to a Stamp Mill. There the ore would be crushed to about the size of sand. This stamp sand would be placed in water so copper could sink to the bottom because it’s heavier. Then copper would go to the smelter to be melted into shapes to sell. The remaining sand went into a local lake that used to be one of the deepest in the nation.

The waste, or stamp sand, was deposited into Torch Lake. Copper concentrate was then transported to the Quincy smelter for final purification, casting, and shipment by the Portage waterway.

While at the Quincy Mine, we got to go through a restored miner’s home. The miner, his wife, and their 9 children lived here. Sounds crowded to me.

Across the street from the mine are some old, worn down buildings from the time of the mine. It was a huge, profitable operation for many years!